TrueView 660

£142,618.18 excl. VAT

Advanced LiDAR Technology

Dual Drone and Mobile Mapping Capability

Triple Calibrated Mapping Cameras

Survey Grade Sensor

The TrueView® 660 is GeoCue’s third generation RIEGL integration built with the

miniVUX-3UAV and triple mapping cameras (right, left, nadir) for high accuracy

mapping with excellent vegetation penetration and wire detection in a lightweight payload package. In addition, you can upgrade to high-resolution Sony

RX1R2 or Sony a7r imaging camera for even higher performance.

High-Accuracy RIEGL Sensor

Built with the miniVUX-3UAV, the TrueView 660 offers a 300 kHz pulse rate at a 120° LiDAR FOV. It provides 15 mm accuracy and typical 10 mm precision, making it ideal for the most demanding engineering-grade surveys.

Triple Camera Colorization

The system features three mapping cameras (right, left, and nadir) that provide true colorization over a 113° FOV. The calibrated Sony mechanical leaf shutters minimize motion blur for crystal-clear results.

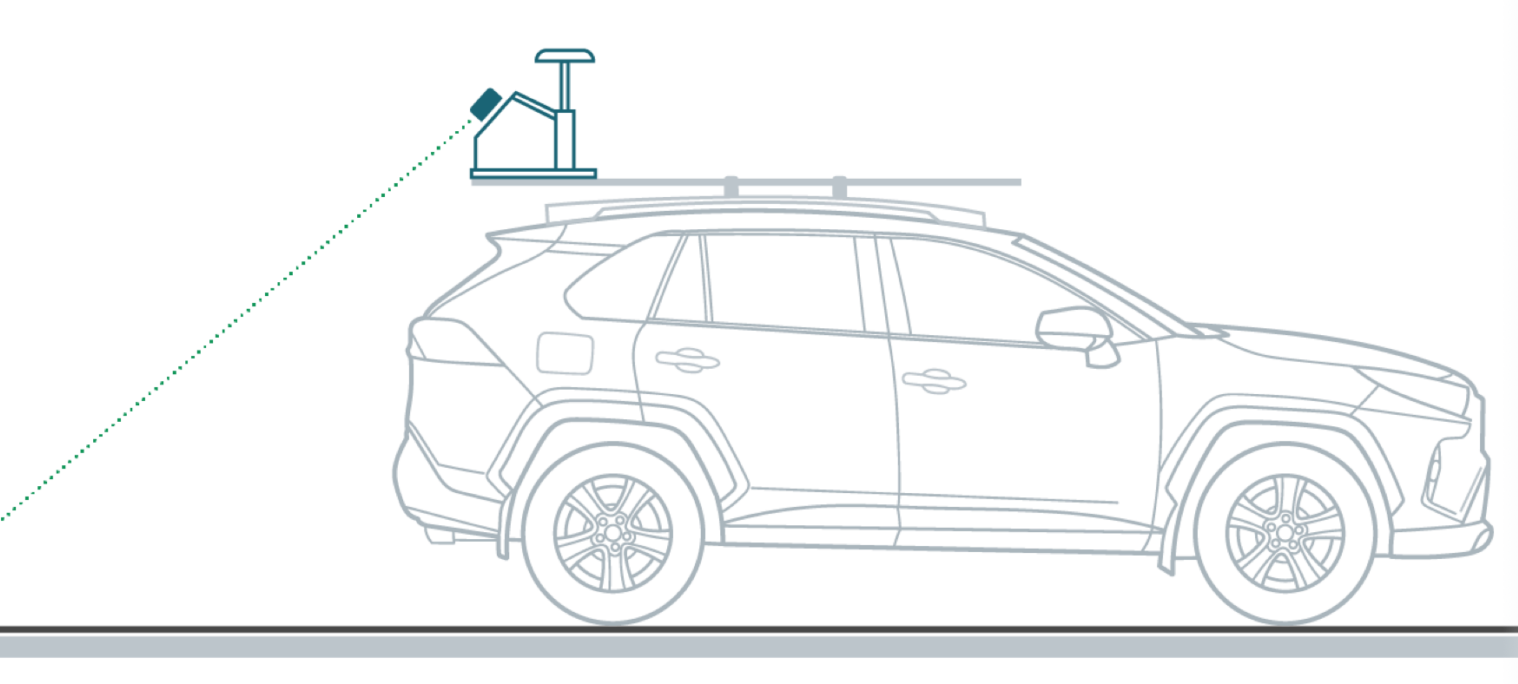

Dual Drone & Mobile Capability

This system is uniquely flexible, offering optional mobile mapping capability alongside its standard UAV configuration. Its lightweight 2.6 kg payload ensures compatibility with a wide range of drone brands, including DJI, Freefly, and Skyfront.

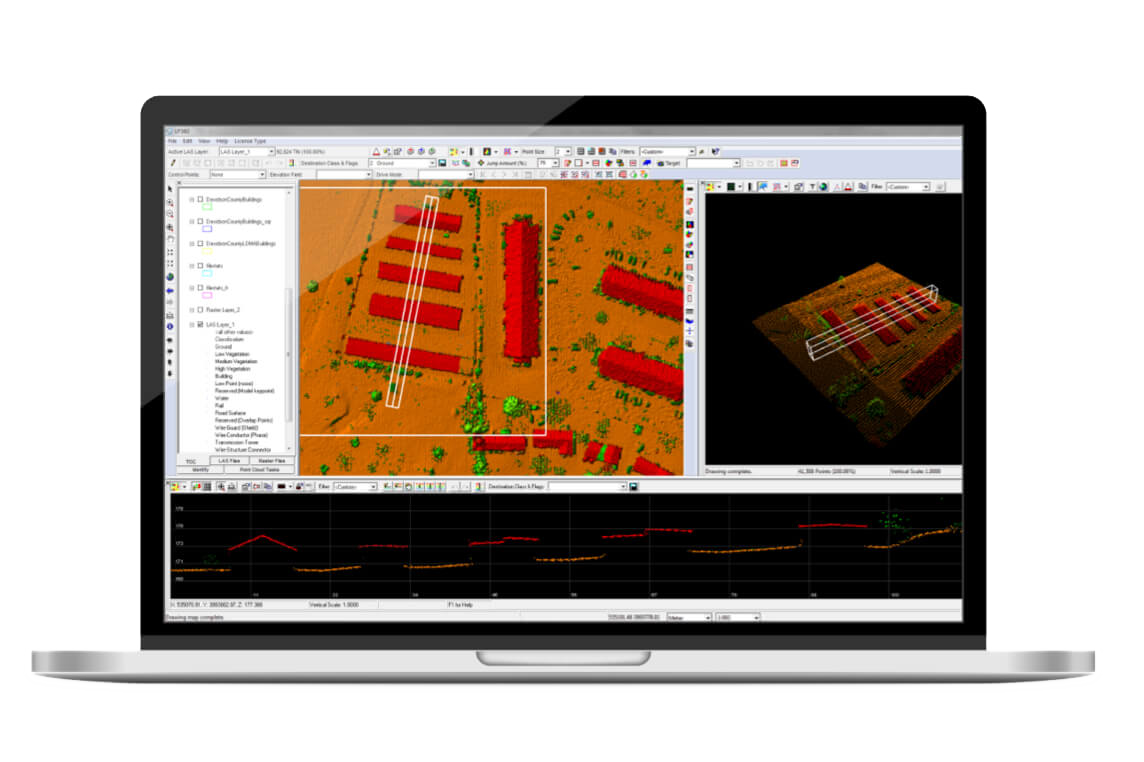

Powered by LP360 Drone

The TrueView 660 comes fully integrated with LP360 Drone, including professional processing modules like Strip Align, 3D Accuracy, and Photo. This allows users to post-process raw flight data into colorized, georeferenced 3D LiDAR point clouds and high-accuracy orthomosaics within a single, simplified workflow.

Precision for Critical Infrastructure

With its excellent vegetation penetration and superior wire detection capabilities, the TrueView 660 is optimized for Rail Inspection, Powerline Wire Extraction, and Road Design. It is NDAA-compliant, ensuring it meets the security requirements of high-level government and enterprise projects.

Featured Applications

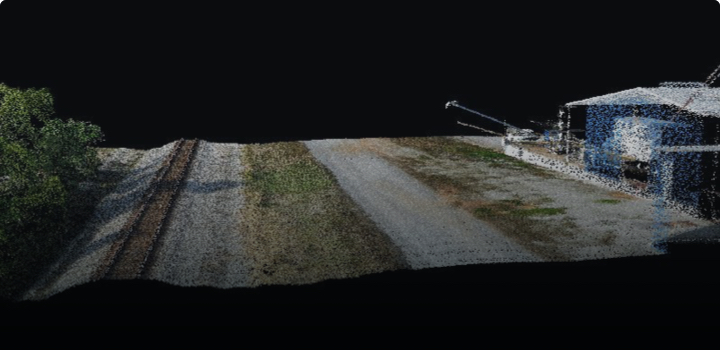

Flexible field operation with optional mobile vehicle mounting

In complex project environments, there are times when drone flights aren’t possible—such as in dense, high-population areas or restricted zones. In these cases, the sensor can be deployed in mobile mapping mode.

For projects requiring multiple viewpoints and enhanced detail, combine both drone and mobile LiDAR modes. This hybrid approach delivers comprehensive coverage—the best of both worlds—to accurately recreate your environment.

Specifications

| Specification | Value |

|---|---|

| Data Collection | LiDAR + Imagery |

| LiDAR Scanner | RIEGL miniVUX-3UAV |

| LiDAR Beams/Returns | Up to 5 per outgoing pulse |

| LiDAR Range - usable | 100 m for targets with > 20% reflectivity |

| Positioning and Orientation System | (660) Applanix APX-20 |

| Pulse Repetition Rate | Up to 300 kHz (selectable)* |

| Scanner Performance |

|

| GNSS/INS Performance |

660

|

| System Performance |

|

| Camera Sensor | 3 Sony IMX-183: 1”, 20 MP, RGB -> 60 MP per payload ***Optional upgrade to high-resolution Sony RX1R2 or Sony a7r. Ask your salesperson for details. |

| Mass | (660) 2.6 kg (IMU-90) or 2.8 kg (IMU-82) (with standard 3 camera package) (payload unit only - no accessories including battery, mount, antenna, power adapter) |

What's included

Accessories Parts

TrueView 660 LiDAR Sensor Payload

USB Thumbdrive

GNSS Antenna

Sensor Hardcase

Concentric Target

Software/Data Management

LP360 Drone Processing Software

Includes Strip Align and Photo Add Ons

Support

1 year of hardware and software support

Drone Platforms

The TrueView 3D Imaging Sensors are designed as a lightweight payload, offering flexible integration with a wide range of drone platforms. Geocue has worked with several drone manufacturers to help provide customers with a complete drone mapping solution. If your preferred brand isn't listed, get in touch with our team to discuss custom integration options!